-

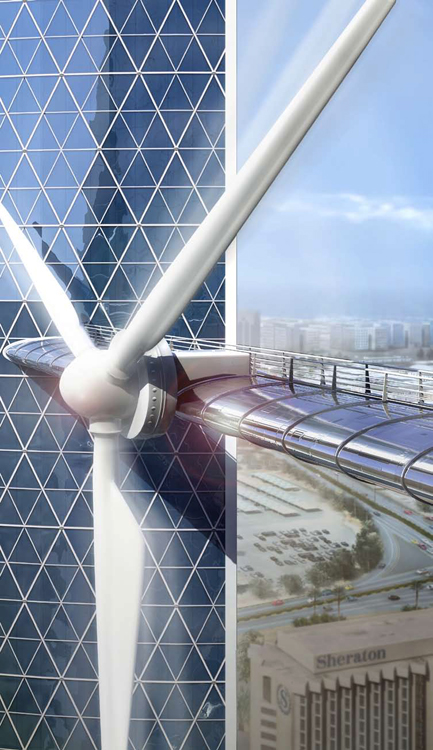

All about the mills around the World ⁄ Harnessing the wind: Bahrain World Trade Centre

October 3rd, 2008

Manama, Bahrain

Bahrain’s World Trade Centre is one of the first buildings to be designed with wind turbines as part of its structure. It sounds simple, but as Thomas Lane discovered, the problems were many and the answers elusive

Constructing the world’s first building to sport large integrated wind turbines in the most oil-rich region on the planet seems crazy. Just knowing there is so much oil under your feet makes profligate behaviour seem natural: people drive their gas guzzlers on journeys of a few yards and everywhere you go, super strong air-conditioning is engaged in an endless battle with 50°C temperatures. But the fabulous oil wealth of the Middle East also means clients have the money to try something different. So, when you put together a sailor inspired by the power of the wind at sea, and a wealthy client with the money to realise crazy dreams, the idea starts to look more plausible.

The initial concept

This is how it happened. The client, who wants to remain anonymous, invited architect Shaun Killa, sailing enthusiast and design director of Atkins Middle East, to a piece of land near the Gulf coast in Manama in Bahrain to discuss its redevelopment. “When I went, a tremendous wind was blowing – it was at least 25 knots,” says Killa. “It was very clean and uninterrupted, coming off the sea. It was clear to us that the opportunity was there to create a building that would harness that wind.”

The obvious option in such a sun-blessed country would have been solar power, but Killa explains that his choice of wind was based on sound logic as well as instinctive enthusiasm. “Four years ago photovoltaics were very overpriced – about five times as expensive per kilo watt than wind,” he says. “There were also issues about PV panels losing their efficiency when they got hot. I didn’t think they were ready for the Middle East, so it had to be wind.”

Fortunately, he says, the brief for the Bahrain World Trade Centre was very fluid: to create a new, upmarket shopping mall linked to an existing one, plus add “50,000m2 of useable space in an office building.”

“The client didn’t specify how many buildings,” says Killa. But even in the Middle East clients are careful not to chuck money away on mad schemes. Killa and his team had to prove the idea was going to work, which was a tough job when it had never been done before.

This required a huge amount of research. The team opted for as many standard components with proven performance records as possible, to keep the client happy and the project manageable. These components included the control systems, the mounting bridges for the turbines and, crucially, the actual wind turbines, which were a type used on early wind farms. “They needed to be rated and certified,” says Killa. “If we chose anything that wasn’t, there would be five years of research and development, and I don’t believe any client would sponsor that.” This meant the building had to be designed around turbines that were intended for a different environment to an office building. “We had to take a wind turbine that was built for a field and create a near perfect environment for it,” explains Killa.

How would it work?

Research showed that about 70% of the wind coming off the Gulf hit the coast head on or within a 60° range on either side. This confirmed that the planned development would work well on the site, but only if the building were designed to straighten out any winds coming in at a slight angle, in order to hit the turbine blades head on for maximum efficiency.

The solution was to create two separate wings with the wind turbines sitting on bridges between them. These two elements are shaped like aerofoils, angled so the distance between the wings is 120m at the front but just 30m at the rear. This creates a funnelling effect that, aided by the shape of the wings, straightens and channels the wind. The outer edges of the wings are also aerofoil-shaped, which creates an area of low pressure just behind the wind turbines. Killa says the design not only directs the wind, but also increases the wind speed so that up to twice as much energy can be extracted from it by the turbines.

Every part of the development has been designed to maximise the effectiveness and efficiency of the turbines. The building has been carefully shaped so each of the three turbines rotates at the same speed. This means that each is generating the same amount of electricity, simplifying control and power conversion systems and ensuring maintenance schedules are the same. Because the wind speed increases towards the top of the building, it tapers to lessen the funnelling effect, keeping the wind consistent over the building height.

Safety first

Deciding the building shape was only the beginning. There were a huge number of questions that had to be answered. Would the turbines create airborne andstructure-borne noise? Could they deflect and hit the bridges? What would happen if the blades were struck by birds or lightning? Would the flickering caused by the turbine blades cause someone in an adjacent building to have an epileptic fit? The list goes on, covering about 200 possible scenarios. “The threshold we always set was safety and user comfort,” says Simha LytheRao, Atkins’ project manager.

Each scenario was carefully risk-assessed to determine how much risk was acceptable. The team also looked at each part of the building and listed what events could affect it. If the risk seemed too great, measures were put in place to reduce it. For example, there was a high risk that vibrations from the turbine gearbox would be transmitted into the building structure by way of the bridges and would be audible to the occupants in the same way as someone drilling into a wall several floors away. The solution was to mount the turbines on rubber and isolate the bridges from each wing using rubber dampers, which also accommodate the differential movement between the two wings. In addition, lasers are used to monitor the turbine blades; if these get too close to the bridges, the control system shuts the turbines down.

Another big challenge was coming up with the control system itself. There are existing systems for turbines, and for buildings, but nothing that links the two together. Uniting the two was important, as the control system needed to tie the turbines’ output with the electrical demand of the building. Safety issues also came into play, as the turbines need to shut down if there is a fire, or if someone opens one of the doors from the building onto a turbine bridge. “Nobody thinks about the integration of the controls but it was the most difficult part,” says LytheRao. Turbine supplier Norven worked with Atkins to develop a system that would cope with all these requirement by working with the building management system.

Testing the wind

The crunch moment came in April, when the turbines were switched on briefly to see if all these issues were successfully resolved. “We ran the turbines for 14 hours. There was no vibration or noise at all and nothing which was a concern,” says LytheRao. Killa adds that the turbines produced more power than predicted, spectacularly vindicating his vision and the team’s hard work (see box: How much power does it produce).

The building is scheduled for completion at the end of the year and is apparently fully let. Was all the work worth it? Killa thinks so. He has also been surprised by the positive response the building has received from locals, and from other parts of the Middle East. “We were told unofficially that a lot of the leaders in the Middle East started to see this as the future,” he says. “There needs to be a new consciousness. This building’s success has contributed to a lot of the green initiatives in the region.”

The new wave of eco-enthusiasm he refers to includes zero-carbon city Madur in Abu Dhabi and the new green regulations in Dubai, plus a rash of new, low energy buildings such as the Dubai International Financial Centre Lighthouse (see box: What’s next). Making the Middle East’s inhabitants think more carefully about the oil beneath their feet is no mean achievement.

Tis publication is from Bahraingateway page

Issues with the Trade Centre:

Bahrain - 2005

Bahrain - 2006

Bahrain - 2008

Bahrain - 2009

Bahrain - 2012: first & second issue

Bahrain - 20132009.01.31